Customer Journey: a repetitive task

Post 6

The artworks here are provided by the very talented artist Wilustrador. I found and contracted him using Fiverr. The cost for the work was about 500-600 USD/EUR. I’m really happy with the result as it brings the whole idea to life.

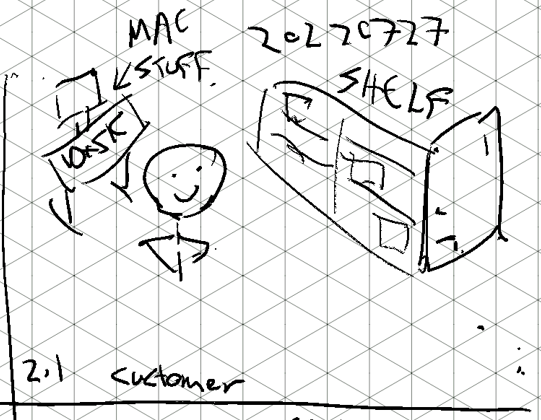

This started out as a very scrappy set of sketches on my reMarkable. The idea was to have a storyboard for a user story.

It's been a several month process to boil it down to this simple customer journey, with all the details and reasoning pushed to future posts.

Anyway, result is way cooler than I imaged it would be. I hope you enjoy. 😊

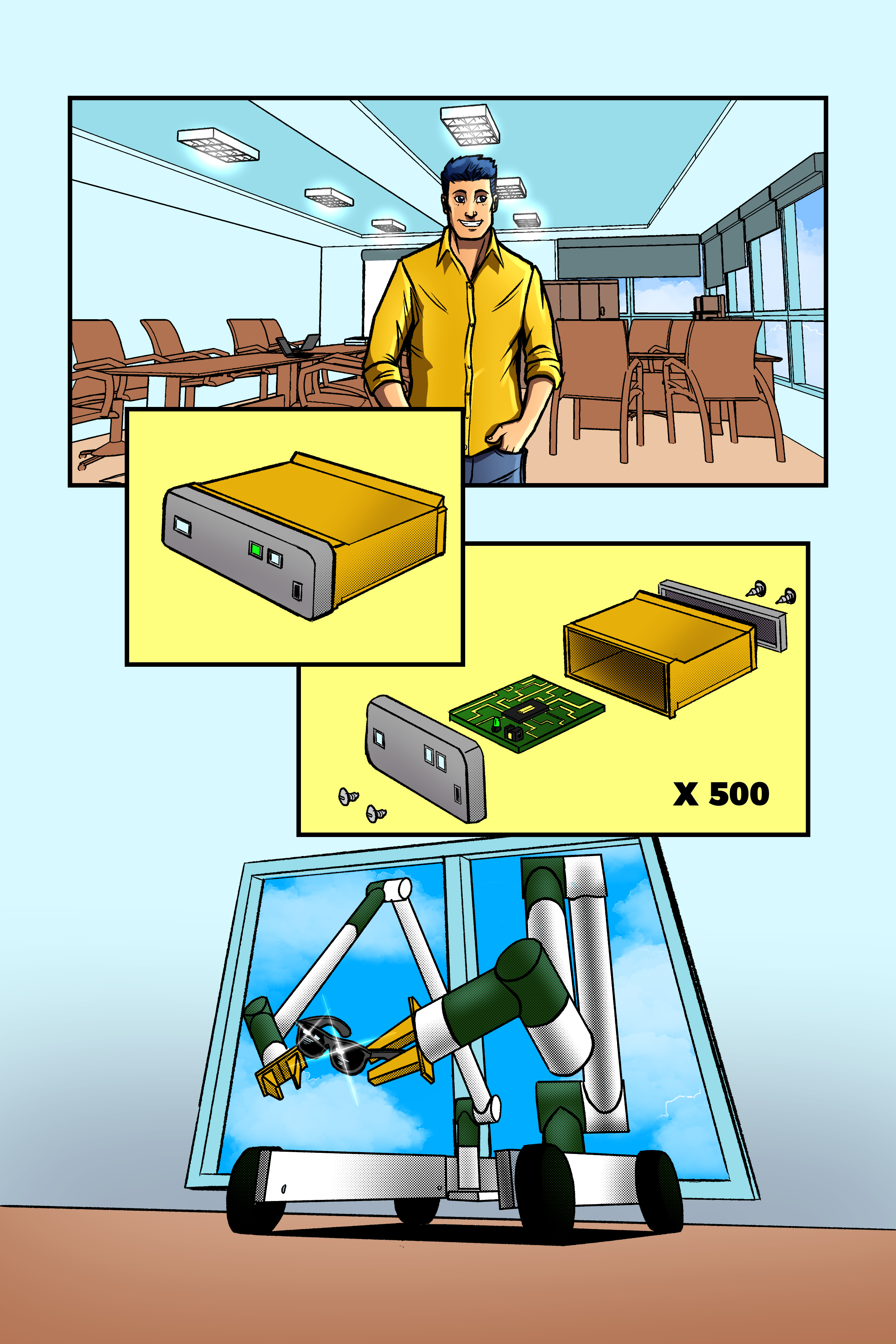

Our customer has a small business making all sorts of gadgets. For one such project, he requires 500 units to be assembled from a few parts. Rather than contract a person or outsource to a factory, he decides to order a robot to perform the work.

(But why? : a link to discuss this will go here )

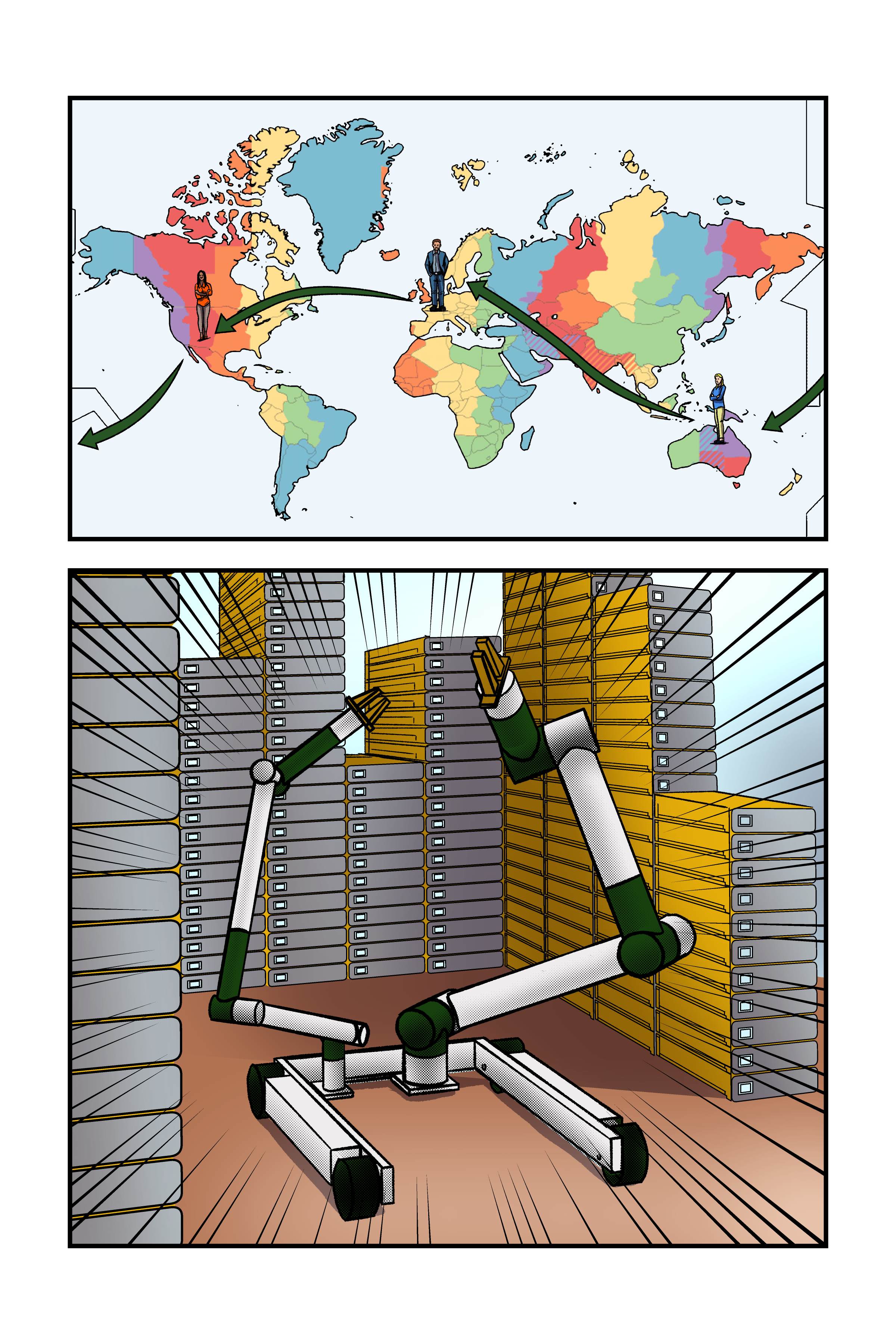

Enter our team to help out. This is the robot operations centre. The customer calls a business builder to discuss the scope of the project and hopefully book a robot. Then the robot is delivered to the customer’s office. It will then be controlled remotely by a dedicated robot driver who works from the Operations Centre.

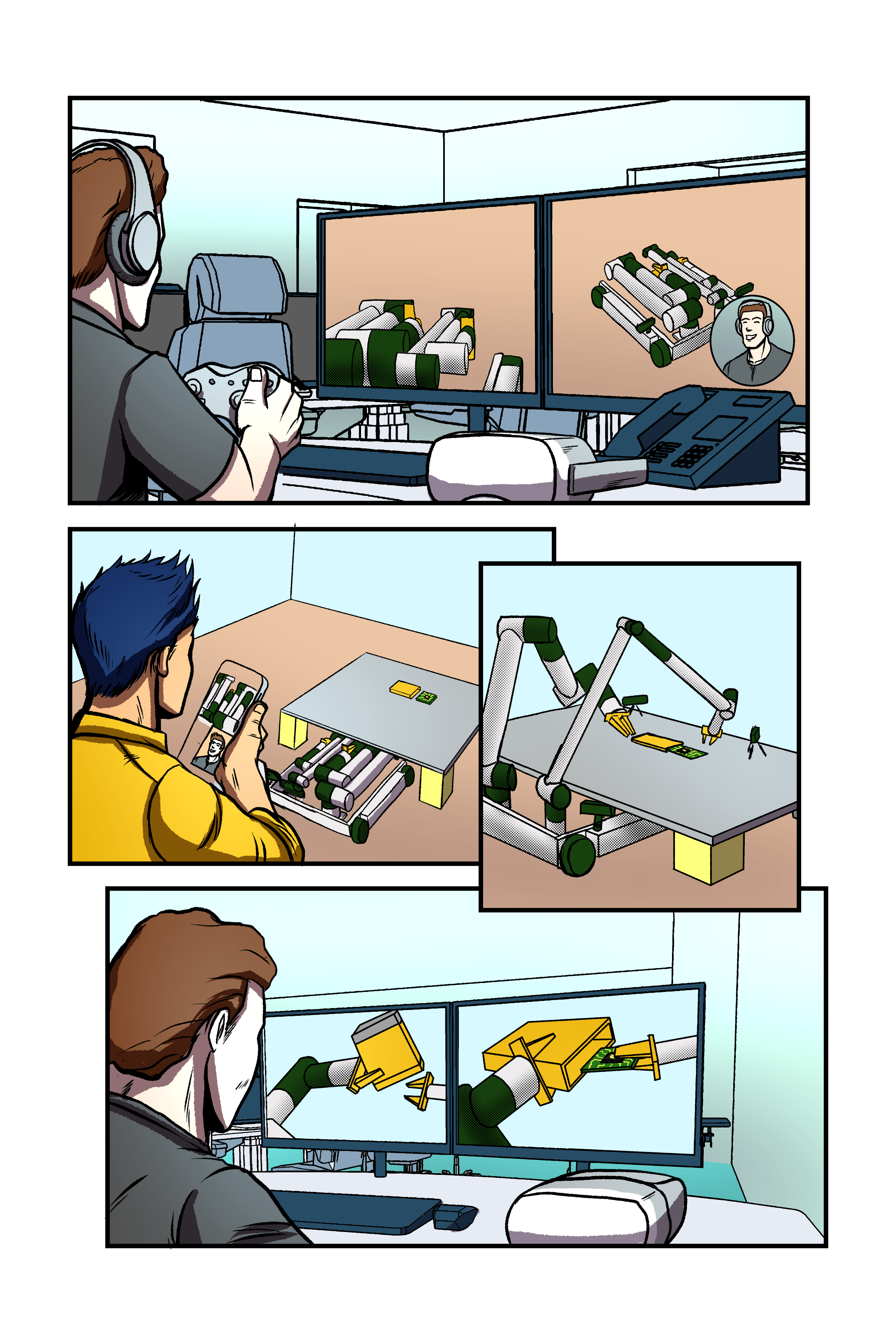

Once the robot is on-site, the robot driver and the customer take a video call. Together they guide the robot to the workstation.

At the workstation, the robot sets up some portable cameras to get a good view of the project.

Then, assembly work begins immediately and the customer can now leave to focus their attention on other projects.

The robot driver is now remotely assembling the gadgets.

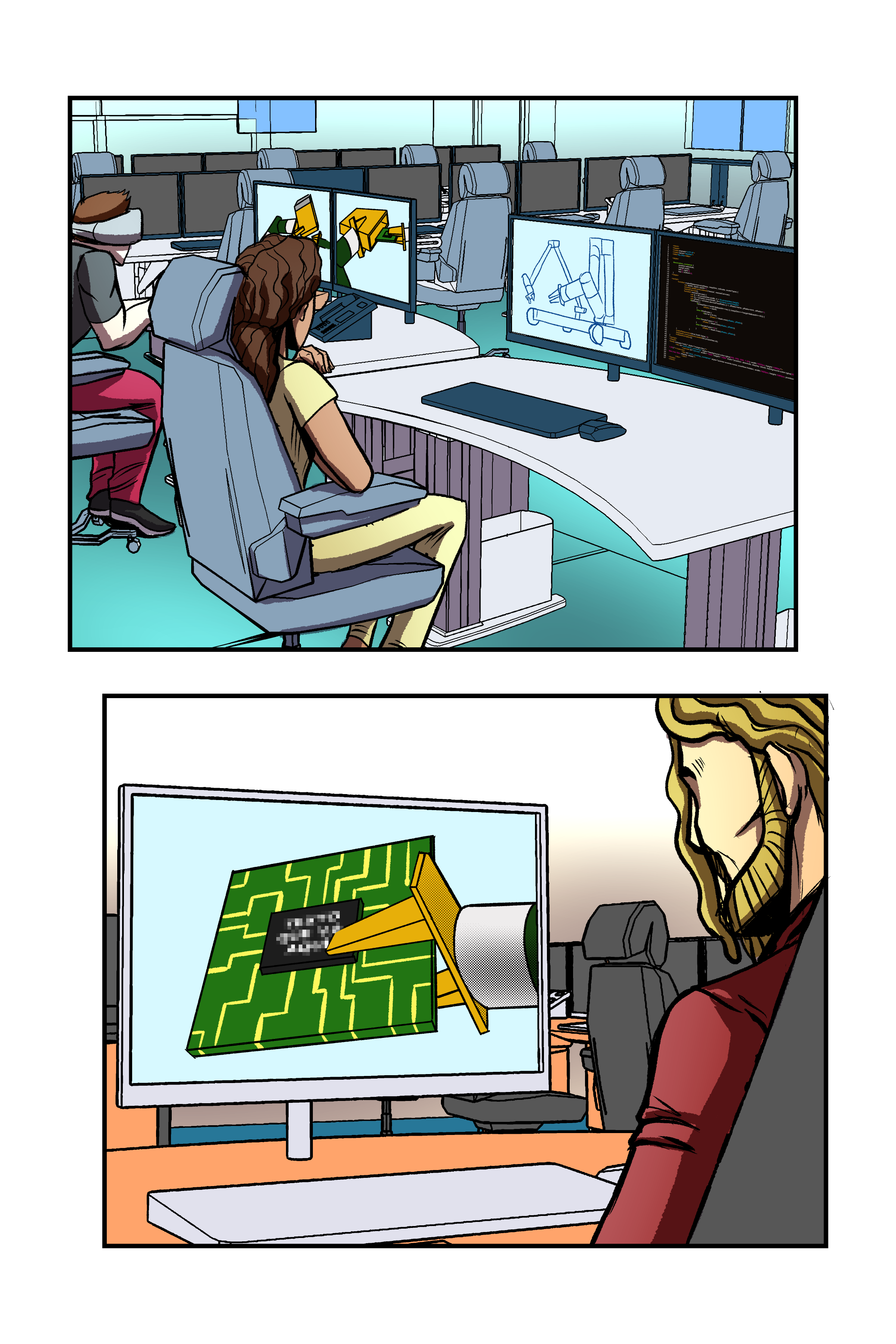

While the robot driver begins the “hands-on” assembly process, an optimisation specialist begins the process of collecting data so that the task can be automated.

First, she will break the task down into small steps. Then, she will then begin to outsource these steps to experts or to software that will automate the work.

Furthermore, all the data is collected for AI training. Gradually the hands-on work is reduced, and automation takes over.

As an add-on service, she has also sourced a third-party for inspection of the work. Part of his view is obscured using a privacy filter (the white pixelated text). This feature enables the customer to protect sensitive data while still benefiting from third-party services.

By the end of the first day, most of the assembly work is being automated using low-cost methods. The remote responsibility is then handed over to follow-the-sun robot operations. This 24-hour safety and quality monitoring service allows the project to continue, even when the customer has left for the day.

When the project is finally complete, the robot goes home like any other employee (for maintenance and upgrades 😂).

Included in the service is a professional quality assurance report with a full assembly video of every unit produced.

It’s all about the data.

In the end, the service is intended for on-demand medium-sized tasks. It competes on reliability and traceability by providing 100% documentation on everything it does.

The robot will very often compete on cost and delivery time, right from day one. However, the unbeatable value will come over time as all data is collected from multiple jobs and used to continuously train and improve automation methods.

The end.

...

...

P.S.

Producing this was a lot of fun. The next post is a 'making-of' post about how this was put together. It is a very long post and its "subscribers only"... oooOoOoo...

It includes all the original ideas and sketches, such as this one: